How You Can Craft Durable, Built-To-Spec Light Foundations

Growing, diversifying, or starting your business is simple with Pole Base’s smart, straightforward equipment and production processes.

Equipment: The Basics

The classic, industry-standard round light pole base form and its related components serve as the foundational piece of equipment that kickstarts your Pole Base production journey. But this isn’t just any other form.

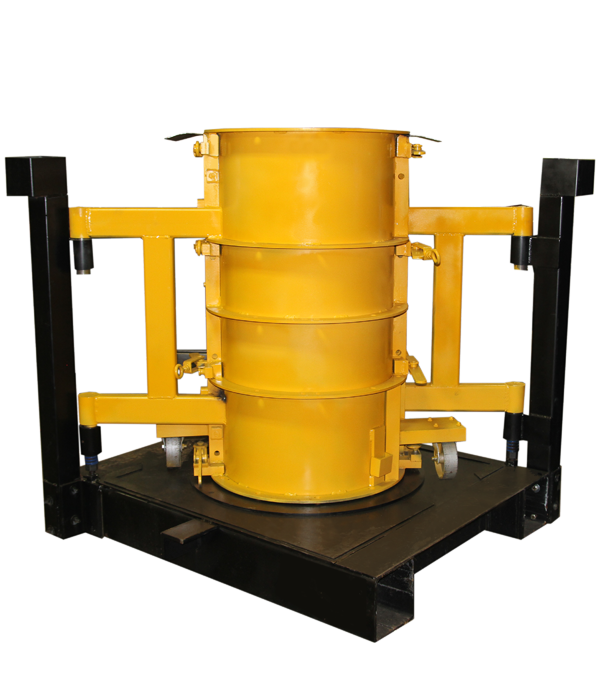

24-Inch Round Smooth Form

Produces the round smooth and round rusticated (rustication strips included) Pole Base light foundations.

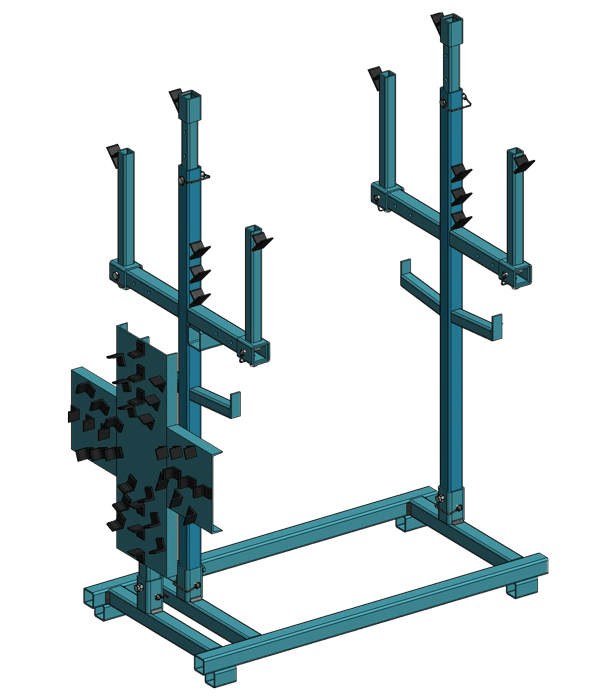

Rebar Jig

Speeds assembly of rebar cages for 18, 24, and 30-inch (457, 610, and 762-mm) diameter bases.

Rollover Donut

Ensures safe and easy transitioning from vertical production orientation to horizontal transport position.

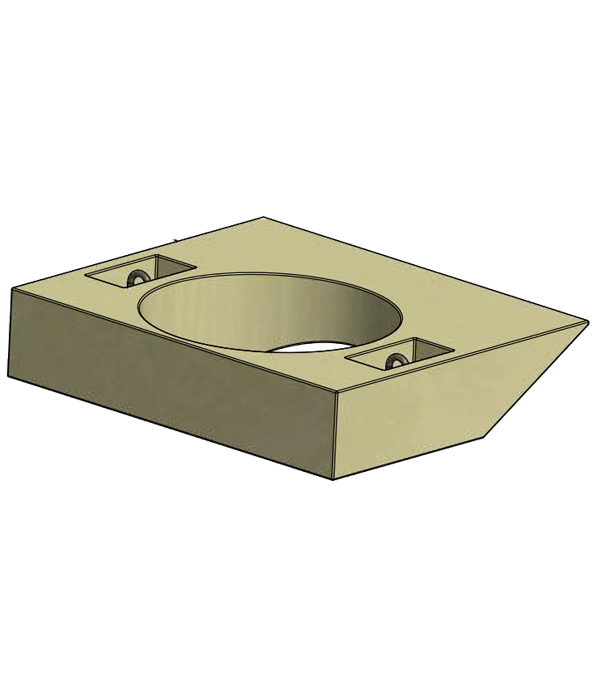

Lifting Plate

With a working load limit of up to 10,000 lbs (4536 kg), allows the lifting and movement of cured bases with a variety of bolt patterns.

You Can’t Fake Pole Base

With magnetic conduit retainers, height extenders, and a variety of anchor bolt receivers and door diameters, Pole Base’s customizable components make it the clear choice over makeshift homemade forms.

You might be quoted less for plastic precast forms, but you'll pay for it later. Pole Base's high-quality, hand-crafted steel forms will deliver consistent performance pour after pour, ensuring you're always delivering bases that meet or exceed your customers' project demands.

Pole Base Production

Enough talk. How about a look? See how simple it is for you to produce built-to-spec Pole Base light pole foundations without modifying homemade forms for every project.

Take the Next Step

Considering producing Pole Base? How about giving us a chance to produce a price that aligns with your vision and market?